What is the Difference Between ECT and BCT for Corrugated Boxes?

The main role of corrugated packaging is to protect and transport goods as they travel from manufacturer to end user, potentially making several stops along the way. For many reasons, ensuring that the integrity of a corrugated box is an appropriate match for the product it holds is a crucial step in developing custom packaging. Too big or too hefty of a material and you’re paying for extra weight and space. Too small or too slight of material and you run the risk of damaged or failed boxes (and potentially damaged goods).

Material strength is one of the main aspects by which the effectiveness of a corrugated box is measured.

Boxes are made from corrugated fiberboards, which are comprised of a wavy (corrugated) layer of paper, sandwiched between two outer paper liners. Corrugated fiberboard comes in different flute sizes, which results in different board thicknesses.

The strength of a corrugated board can vary based on the flute size, the weights of the papers used by the corrugator, and the composition of the materials used. For example, 100% post-consumer recycled corrugated is not as strong as fiberboard made from virgin materials. This is because the recycling process breaks down the paper fibers that make up the pulp, resulting in shorter fibers that cannot withstand as much pressure.

But how is the strength of a box made from corrugated fiberboard actually measured, and why does it matter?

What is ECT?

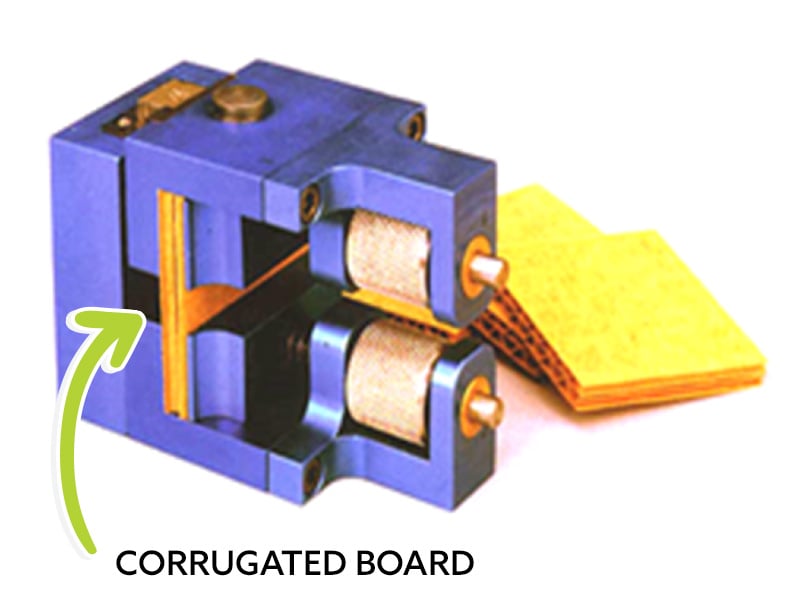

An Edge Crush Test (ECT) is used to evaluate the strength of a corrugated board by measuring the cross-direction crushing of a given sample size under laboratory conditions following a TAPPI/ASTM standard test. This method provides data on the ability of a particular board construction to resist crushing under the vertical pressure that comes with being stacked. ECT is the industry-wide standard for benchmarking the “stacking strength” of the various grades of corrugated board. ECT is measured in pounds per lineal inch of load bearing edge (lb/in), however it is typically expressed as an ECT value such as 44 ECT. This value is then used to calculate a box’s theoretical compression strength.

Image courtesy of Ralph Young / AICC

In layman’s terms, ECT estimates the minimum amount of vertical pressure required to crush a corrugated box. This test is a relevant measure of strength for most boxes, as they have to withstand being stacked on pallets, in shipping containers, and in delivery trucks before they reach their final destination. That’s a lot of pressure!

However, ECT is not the only way to estimate the relative strength of a box, and it may not be the only data point worth considering when designing your own custom packaging.

What is BCT?

A Box Compression Test (BCT) looks at the problem a little differently. Instead of expressing the strength of the corrugated board without consideration of the product it’s carrying or the format of the box, BCT values communicate the performance that a company needs to get out of that particular piece of packaging. BCT takes into account such variables as what is going into the box, how the box will be stacked or palletized, and the lifespan of the box to produce a target compression value that meets the expectations of the customer.

Image courtesy of Kruger

For example, a company may require a box with a BCT value of 500 pounds. This allows a manufacturer to meet this requirement in any number of ways by identifying combinations of materials, sizes, and structural designs that result in a box with a BCT of 500. Rather than focusing on box material as the single indicator of strength, BCT looks at the big picture and takes many other factors into consideration to arrive at a more accurate solution.

Image courtesy of Ralph Young / AICC

Three boxes with identical ECT values but different BCT values.

Which is a Better Measure – ECT or BCT?

At the end of the day, ECT and BCT are two different ways of estimating the performance of a box, and both can provide valuable information when developing your own custom packaging.

As a brand, it is most important to be able to rest assured that your box won’t fail under the weight of your product or be crushed in shipping. Therefore, choosing a packaging provider who can work with you to clarify the specific performance attributes your packaging must meet and then deliver a solution that meets those goals is key to your success.

As you are ramping up your business, ECT may offer enough data to generally provide guidance for your shipping box development. As your company matures and you can provide your packaging manufacturer with greater detail on product palletization and logistics, you may consider evaluating your current packaging under the lens of BCT in order to refine the box to a more relevant set of performance conditions.

Tailored Solutions for You

The BoxMaker’s award-winning team of structural designers are ready to help you evaluate your current packaging and assess its performance tailored to your specific supply chain needs. Contact us today to get started.

Subscribe

Share this post

Similar Articles

Exploring F-Flute: A Game-Changer in Retail Packaging

Learn about the features of f-flute corrugated and the benefits this material delivers to retail pac …

Packaging Design Considerations for Baby Boomers

Baby boomers control an estimated 70% of all disposable income in the United States. Learn how to ca …

What Are Custom Boxes? 4 Key Benefits for Your Brand

Investing in custom boxes is more than an expense; it's a strategic move that yields considerable be …