The Sustainability Benefits of Digital Print for Corrugated Packaging

In today's climate-conscious world, brands are under increasing pressure to rethink their packaging strategies and adopt more eco-friendly solutions. As the need to reduce environmental impact has never been more pressing, sustainable packaging has become a critical priority for businesses across industries.

Amidst this growing demand for sustainability, digital production emerges as a modern solution that complements this demand. Unlike traditional printing methods that rely on print plates and generate significant waste, digital production offers a more efficient and eco-friendly approach.

In this article, we'll explore how digital print and finishing is transforming corrugated packaging, highlighting how it can strengthen sustainability efforts while meeting the evolving needs of businesses and consumers.

What is Digital Print?

Digital print is a direct-to-board printing method that utilizes inkjet technology to print directly onto corrugated material without the use of print plates. This differs from traditional analog printing techniques like flexography and lithography, which require physical printing plates and often generate more waste during setup and production.

Thanks to this distinction, digital print offers several advantages that other methods cannot match.

The Benefits of Digital Print

Digital print technology not only streamlines the packaging production process but also elevates the quality and customization options available to brands. Here's a closer look at the key benefits:

Speed

The HP PageWide C500 Press can print up to 1,800 corrugated sheets per hour, allowing orders to be produced and shipped in a matter of days rather than months. This just-in-time production model reduces the need for large inventories to be produced and the associated warehousing and handling requirements that go along with them.

The efficiency gained from digital printing accelerates time-to-market for products, ensuring that brands can swiftly respond to market demands and consumer preferences.

Agility

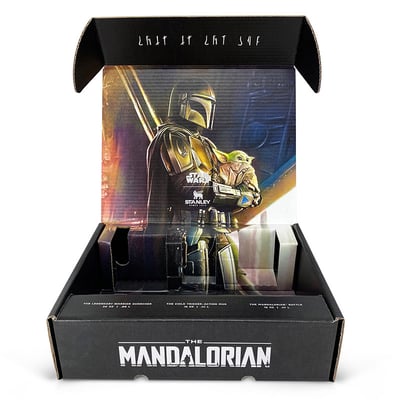

With no print plates needed, every impression can be unique, opening up possibilities for variable data, personalization, and multi-SKU runs. This agility enables brands to customize packaging to market demands and trends, reducing the risk of obsolescence.

Whether it's tailoring packaging designs to specific customer segments, incorporating promotional elements, or adapting packaging for seasonal variations, digital print empowers brands to adapt swiftly and efficiently to changing market dynamics.

Quality

Digital print utilizes the full CMYK color spectrum, allowing for high-definition, full-color packaging designs that are not limited by the number of print plates. This expands the creative possibilities for sustainable packaging that is both visually appealing and environmentally responsible.

Whether it's intricate patterns, photorealistic imagery, or bold typography, digital print ensures that every aspect of the packaging design is rendered with exceptional clarity and consistency. This superior print quality not only enhances brand perception but also reinforces the value proposition of products, enticing consumers with visually stunning packaging presentations.

Digital Print’s Contribution to Sustainability

On top of the mentioned benefits, digital print is also a sustainable manufacturing method that reduces the environmental impact of custom printed packaging in several ways:

Reduced Inventory and Waste

Digital print's just-in-time production model allows for order volumes and replenishment schedules to be tailored to the brand's needs, resulting in optimized inventory, reduced warehousing, and less waste from obsolescence. The less excess production, the better.

No Print Plates

As mentioned above, digital print requires no print plates, reducing the consumption of raw materials and the manual labor required during setup. This significantly conserves resources, enhances operational efficiency, and minimizes the environmental footprint associated with plate production, storage, and disposal.

Perfect Registration

Direct-to-board printing eliminates the need for a registration process. This significantly reduces the number of sheets that are wasted during setup.

Non-Toxic, Recyclable Inks

The HP PageWide C500 press prints with HP True Water-Based Inks, which are non-toxic and fully recyclable, allowing for the safe disposal of municipal wastewater without pre-treatment.

Reduced Water Consumption

No water is needed to rinse print plates after a digital print production run. This contributes to water conservation efforts and minimizes wastewater generation.

Digital Finishing: Eco-Friendly and Agile

Digital finishing is the second part of the production equation. Unlike conventional die cutting, die-less digital finishing via CAD table or laser eliminates the need for a cutting die to transform printed corrugated sheets into finished goods.

Here are several ways digital finishing can reduce environmental impact:

Reduced Raw Material Consumption

For low-volume orders, digital CAD tables can cut and crease corrugated products without any tooling. For higher-volume orders, laser cutting and creasing machines use an economical DART polymer rule for creasing, which requires far fewer raw materials than a traditional wood and steel rule cutting die.

Lightweight Materials

Laser converting produces clean, precise cuts with minimal impact on corrugated board fibers, preserving more of the original material strength than conventional die cutting. This allows for the use of lighter-weight materials that perform as well as their heavier counterparts (when finished with laser vs. die cutting). This further reduces raw material consumption as well as CO2 emissions incurred during shipping due to the lighter weight package.

Streamlined Production Processes

Digital finishing technologies streamline packaging production processes by reducing setup times, minimizing manual labor, and increasing production efficiency. Unlike traditional die cutting methods that require the manufacture and use of physical cutting dies for each packaging design, digital finishing systems can execute cutting and creasing operations directly from design files.

Digital Print and Finishing: The Sustainable Packaging Solution

Digital print and finishing complements sustainability in many ways, such as reducing waste and raw material consumption, delivering inventory agility, offering new possibilities in material and print options, streamlining manufacturing operations, and more.

Brands looking to source sustainable custom corrugated packaging will not be disappointed with the possibilities that digital print and finishing delivers. Contact our Packaging Advisors and we’ll help you get started.

Subscribe

Share this post

Similar Articles

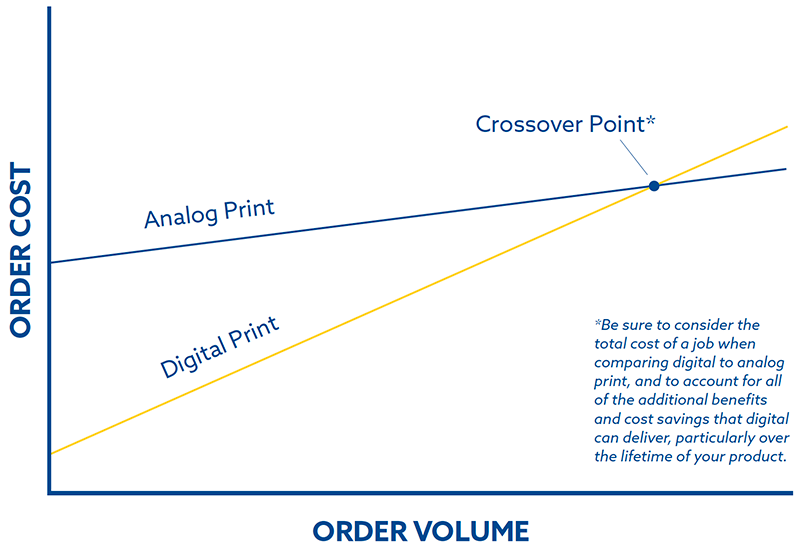

Understanding the Conventional vs. Digital Print Crossover Point

The crossover point at which conventional print is more cost-effective than digital print is changin …

Litho Lamination vs. Digital Print for Retail Packaging

Learn about comparing Litho Lamination vs Digital Print and how technological advancements in digita …

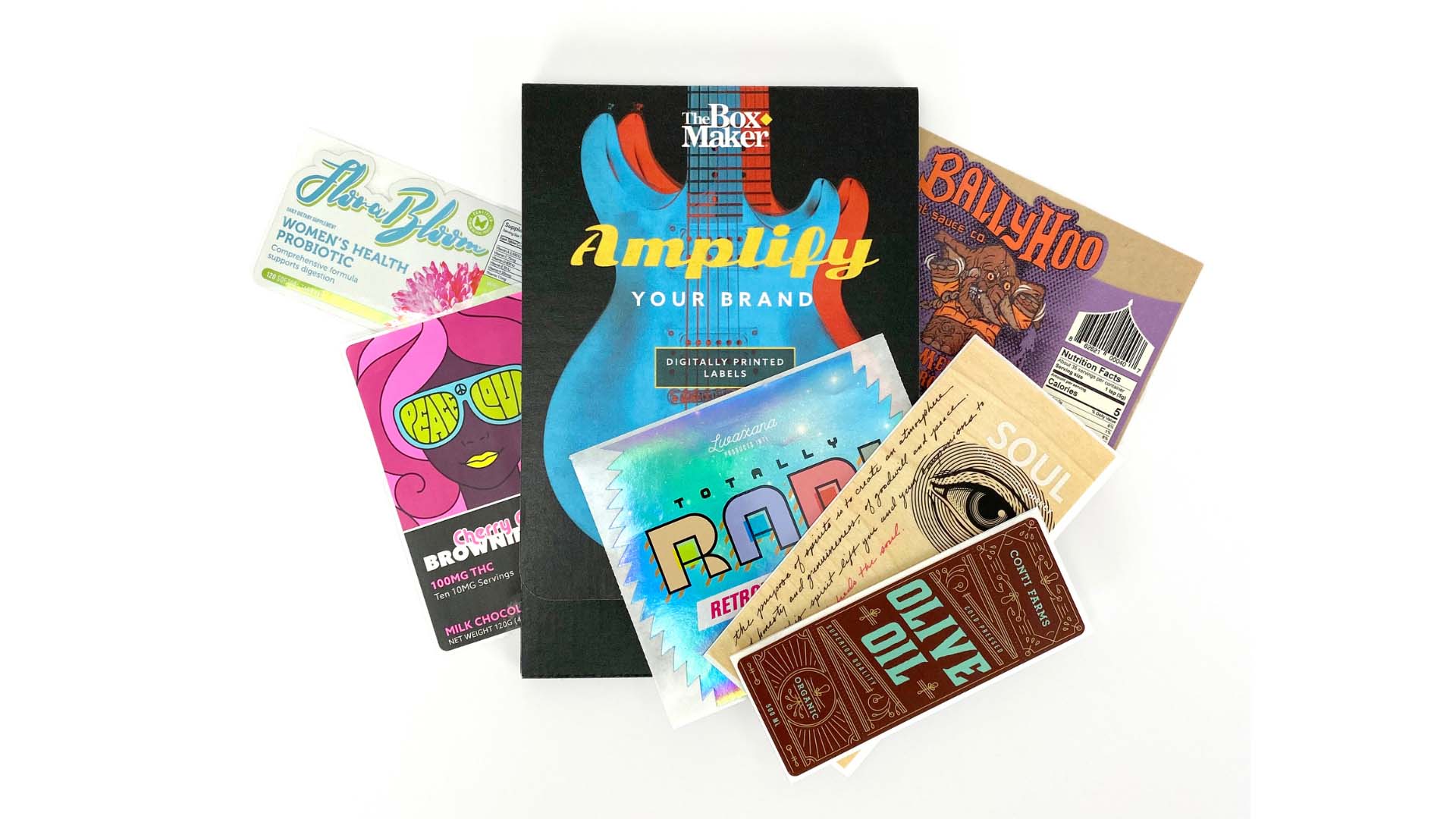

How to Design a Custom Product Label for Digital Print

Master the art of digitally printed custom labels with our guide. Explore essential steps and benefi …