Bluewater Distilling: Streamlining Supply & Growing Sales

Growing a Locally Crafted Favorite

Founded in the Pacific Northwest in 2008, Bluewater Organic Distilling is a community-focused, independent distillery dedicated to crafting brilliantly smooth vodka, gin and aquavit. With a focus on sustainability and artisan techniques, Bluewater has evolved to be the industry leader in quality and integrity.

Time to Thrive

Bluewater Organic Distilling recently partnered with a large spirits distributor in Washington State to grow their wholesale business. The distributor recommended that Bluewater convert their current 12-pack shippers into a 6-pack format to boost sales. This update would not only allow them to offer more competitive volume pricing to their accounts, but the 6-packs are also easier for retailers to use as floor stack displays in the grocery aisle.

Charged with a new packaging directive, Bluewater Organic Distilling needed to update their box structure and packaging graphics in time to ship new boxes to their glass manufacturer for the next round of product bottling and distribution.

Sowing Seeds of Change

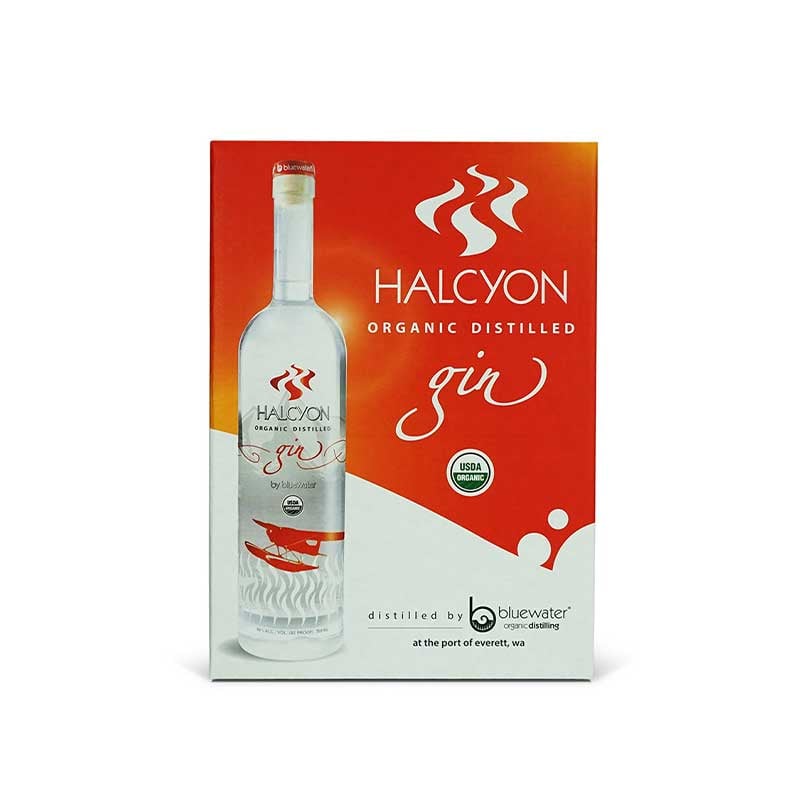

Bluewater Organic Distilling partnered with The BoxMaker to design, print, and ship this order in time to meet the distillery’s tight deadline. Once a structural file was created, Bluewater was able to take advantage of The BoxMaker’s full-color digital print capabilities when designing the graphics for their box and reviewing brand package examples. Previously, the distiller used the same generic box for all six of their product SKUs, the contents of each box only identified by a checkbox on the exterior print. For this new design, Bluewater was able to develop unique graphics for each SKU, making each product more attractive and capturing consumer attention.

Because Bluewater needed to print six different graphic versions of their box and the full-color design required high-quality print, the project was a perfect fit for The BoxMaker’s HP PageWide C500 Press. The C500 offers all the benefits of digital print, including volume and version control, at a print quality that is comparable to litho-lam. Additionally, the True Water-Based Inks used by this press are food safety compliant and a sustainable print option for Bluewater’s boxes.

Volume and Version Control with Digital Print

The BoxMaker printed a total of 8,000 boxes for the initial order from Bluewater Organic Distilling. Within that total order volume, the client was able to leverage the on-demand nature of digitally printed packaging to order each of their six SKUs in different volumes. This gave the brand the flexibility to adjust their order based on SKU demand, rather than having to order a high minimum volume of each art version.

Bluewater Organic Distilling was pleased that with digital print they avoided paying for costly print plates. The agile nature of this print method even allowed for the addition of Bluewater’s recently earned USDA Organic certification to be added to the box designs last-minute before the print run. Bluewater also anticipates easy re-ordering with digital print.

Reaping the Rewards

Early feedback from retailers and wholesale accounts on the structural and branding package changes has been very positive. The new 6-pack structure is easy to use and display, and the bright and colorful graphics are attracting the attention of spirits shoppers. Bluewater Organic Distilling looks forward to a bright future with greater sales and increased market share.

“We are so excited about our new six-pack cartons. The BoxMaker made everything easy to plan and develop, from designing the artwork to allocating the print volume. With their digital printing, it’s nice to have a simpler process and pricing structure and not worry about plate fees and high minimums.”