Litho Lamination vs. Digital Print for Retail Packaging

When it comes to retail packaging, quality counts. Brands recognize that in this fiercely competitive environment, consumers directly engage with their product packaging, be it a corrugated box or a point-of-purchase display. Consequently, both print quality and graphic elements are highly important.

Traditionally, litho lamination (litho lam) has been the go-to print solution for retail packaging due to its ability to provide fine detail in full color across various mediums. Litho lam shines in corrugated packaging and retail displays because it offers an impressive shelf-ready finish. Until recently, litho lam has been the only print method available to deliver this level of quality in high volume.

However, thanks to innovations in digital print, particularly with the HP PageWide C500 press, digitally printed packaging can now compete with litho laminated packaging in the retail landscape in both print quality and scale.

What is Litho Lamination?

Litho lamination is the process of printing decorative graphics onto paper liner board through offset lithography, and then laminating that printed liner board onto a backing board (such as corrugated).

Offset lithography is based on the concept that oil and water repel one another. Lithographic presses utilize two print plates, a positive and a negative, to transfer high-quality color graphics onto a suitable substrate.

The positive plate has a smooth surface that accepts oil-based inks and repels water. The negative plate has a rough texture that absorbs water and repels oil. Rubber rollers are used to extract water from the negative plate and expel the ink from the positive plate. They then transfer the image onto the print medium. A separate print plate is needed for each color (CMYK) to be printed.

Once the sheet is printed, it must be laminated onto a single-faced corrugated board to form the completed corrugated sheet that is ready to be converted (cut and creased, glued, etc.).

The Advantages of Litho-Laminated Packaging

Because litho lamination prints to the liner board before it is attached to the corrugated fluting, it prints on a smooth surface. While excellent for product protection, corrugated material can create a challenge when attempting to achieve fine detail and high-quality full-color print. Historically, litho lam has been the best way to acheive a retail-ready finished product.

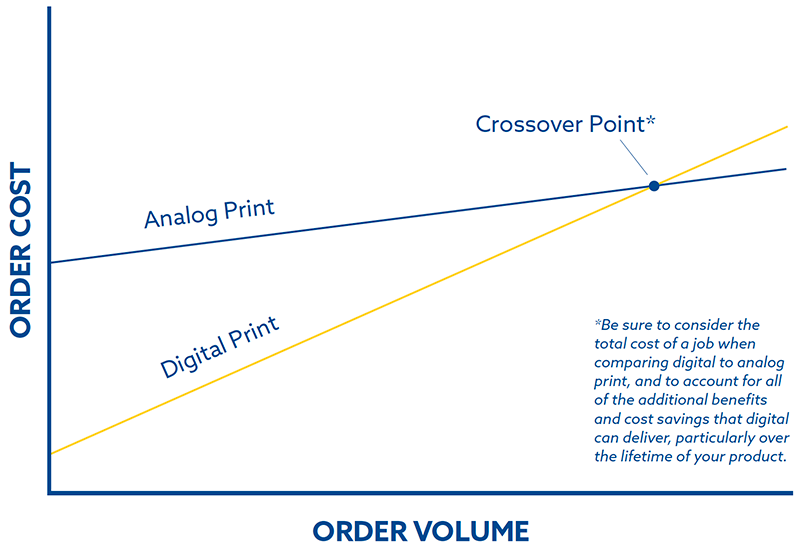

For high-volume print runs, litho lam can be a cost-effective way to produce retail-ready packaging at a large scale. Litho laminated packaging is a common option when a brand requires tens of thousands of identical impressions (or more) without sacrificing quality.

Potential Drawbacks of Litho Lamination

There are things that come with the territory of litho lamination that must be considered when selecting the print method for your packaging project. Because it requires more steps, litho lam often requires longer lead times, higher minimum volume orders to support the setup costs, and the purchase of tooling (print plates). None of these aspects of litho lam are a drawback if your project has ample time, budget, and the right volume to justify the investment.

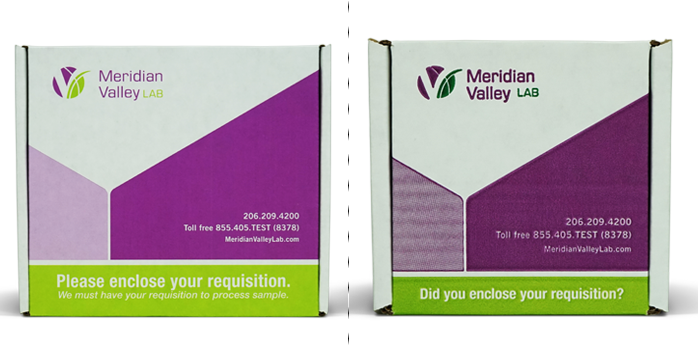

An additional consideration becoming increasingly relevant is customized messaging. Millennials and Generation Z demand more from today’s brands, and a personalized experience driven by packaging can significantly influence consumer purchasing decisions. Because litho lam depends on print plates to transfer images onto packaging (resulting in mass production), creating targeted campaigns comes with a cost. Additional sets of plates must be manufactured and purchased for each artwork variation that is to be printed.

What about Digital Print?

Digital print for wide-format corrugated packaging and display offers many of the same features as litho lam, along with some added benefits.

The Advantages of Digitally Printed Packaging

The primary difference between digital print and litho lam is how ink is applied. With digital print, ink is applied directly to the material surface — in this case, corrugated board. No print plates are required to transfer the image. This method enables many benefits, including:

Fully CMYK color printing: Digital delivers full-color printing at no additional cost per color.

Reduced tooling costs: No print plates must be manufactured and purchased for digital print.

Reduced time-to-market: Digital print is ready to go to press as soon as the artwork file is available – this means your packaging can typically delivered significantly faster.

Variable artwork: Every impression can be completely unique with digital print, opening the door to customized and personalized marketing.

Low minimum order volumes: Digital print is calibrated so that the first impression to the last are identical in quality, and thus order sizes of 1 can be achieved.

High maximum volume order: Digital print has advanced in speed and quality in recent years, and manufacturing plants running the latest equipment can easily produce high-volume orders (think: truckloads).

HP PageWide C500 Digital Press: A New Era of Print

Technological developments in today’s digital presses continue to push forward to deliver the highest quality print at a comparative speed to traditional print methods. These developments unlock the potential of digital for brands that require a scalable solution. Imagine a world where you can launch a campaign with 50,000 packaging units, each featuring a unique artwork impression. With digital print, that world exists today.

Enter: the HP PageWide C500 press.

The C500 Press combines the best of worlds — delivering litho-like print quality with the flexibility and speed of digital print. The C500 press also has the added advantage of using food safety compliant HP True Water-Based Inks. Brands producing products for sensitive applications, such as food and beverage, cosmetics, children’s products, and pet products can have peace of mind knowing their packaging is safe for consumers.

Brands that once relied solely on traditional analog print methods now have the opportunity to explore the possibilities of digital, while maintaining the high level of quality and consistency they expect from litho lam.

The Right Digital Press for the Right Job

The HP PageWide C500 press is the perfect machine to produce digitally printed corrugated packaging at scale. This machine is complemented by additional presses offered by HP, including the HP Scitex 15500 presses, which utilize a larger print bed to produce bigger products, such as digitally printed corrugated retail displays.

It is important to note that every digital press may use different ink types intended for different applications. Be sure to work with a qualified Packaging Advisor who can help you understand which ink type and press combination best fits your particular packaging needs.

Litho Lam vs. Digital Print: Which Print Method is Right for You?

Choosing between litho laminated packaging or digitally printed packaging depends on your specific needs. If you’re running 100,000 identical impressions for a campaign set to launch in three months, litho lam may be the more competitive choice (although digital today is very competitive). If you’re short on time, desire any level of variable graphics, or have specific volume needs, digital print is a great solution.

Every packaging project is unique. In order to produce effective retail packaging, we recommend working with a dedicated Packaging Advisor to develop a comprehensive game plan. Your Packaging Advisor can also help determine if your project is fit for digital print.

Where to Learn More About Digital Print for Corrugated Packaging

The BoxMaker is proud to be a resource for all of your packaging questions and needs. We have been pioneering digital print since 2011 and proudly operate two of the country's largest Digital Production Centers for packaging and display.

If you’d like to learn more about digital print, watching an on-demand BoxMaker University class is a great way to discover new applications for your brand. We host a comprehensive library of classes, each taught by an expert in the field.

Take a look at our upcoming sessions and sign up for our email newsletter to be notified when BoxMaker University comes to your city.

Subscribe

Share this post

Similar Articles

Making the Upgrade from Flexo to Digital Print

Switching from flexo print to digital print is no easy decision. Here are three reasons to make the …

Brand Color Management: How Can G7 Certification Help?

The BoxMaker achieved G7 certification across our wide-format digital printers. Learn how partnering …

Understanding the Conventional vs. Digital Print Crossover Point

The crossover point at which conventional print is more cost-effective than digital print is changin …