Welcome to The BoxMaker

Take a Virtual Tour of The BoxMaker

The BoxMaker began as a custom packaging manufacturer in 1981. Today, we are a leading producer of custom printed boxes, labels, fabricated foam, and other distributed packaging products.

Our Manufacturing Capabilities

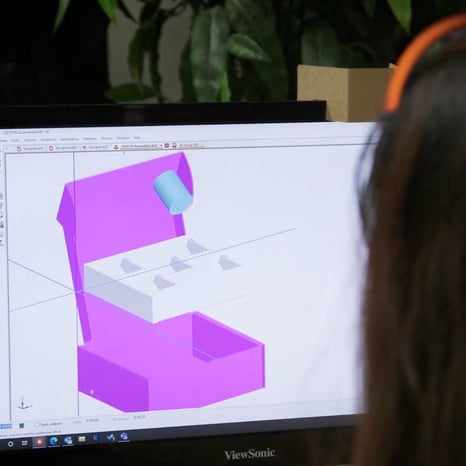

Structural Design

Our award-winning Structural Design team keeps your project moving forward with:

- Expert designers that maximize your custom structure’s protection, efficiency, and visual impact

- A full-time Sample Maker who enables us to quickly deliver structural samples to clients

- Industry-leading 3D modeling/CAD systems and software specific to the packaging sector for full-scale prototypes

The BoxMaker is material-neutral, meaning that we can design across various substances and packaging materials, not just those that we manufacture or convert in-house. Our team provides carefully considered guidance around innovation, use of sustainable materials, and potential alternatives. Cushioning materials and full mock-ups are integral parts of every design project.

Digital Printing and Finishing for Corrugated Products and Custom Labels

Digitally printed packaging opens the door to exciting and creative opportunities for brands. The BoxMaker’s advanced workflow and fleet of state-of-the-art machines enable us to meet the needs of leading and emerging brands alike.

We produce digitally printed corrugated boxes, retail displays, and custom product labels with our industry-leading equipment.

For corrugated products:

- Two HP PageWide C500 Presses

- Two HP Scitex 15500 Presses

- Two Highcon Euclid 5 high-speed lasers for cutting and creasing

- Highcon Beam 2 high-speed laser for cutting and creasing

- A fleet of tool-less digital CAD cutting and creasing machines

For label products:

- Two HP Indigo web presses

The benefits of digital print and finishing for your product sales and supply chain are many. We invite you to learn more about this cutting-edge technology.

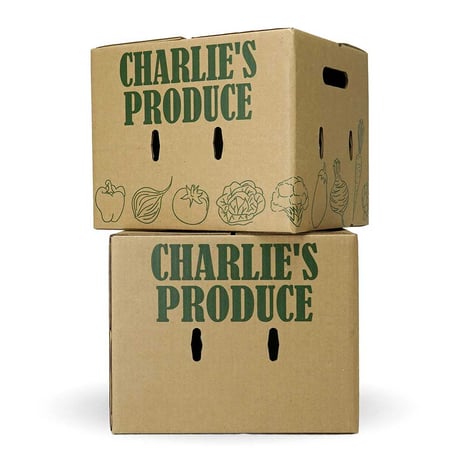

Flexographic Printing

The BoxMaker offers economical, effective flexographic printing for branded corrugated boxes and related products. We print up to two colors at a time on counter displays, case packs, inner trays, and e-commerce shipping boxes.

Flatbed Die Cutting

The BoxMaker offers flatbed die cutting, which operates much like a giant cookie cutter. The cutting die formed of steel rule takes the custom shape of your packaging design. The die stamps your shape out of the corrugated material, creating various structures from a simple rectangular pad to a mailer to a complex floor display with several components.

The Advantages of Flatbed Die Cutting

- Steel dies are less expensive than rotary dies

- 46.5" x 63" sheet size capacity

- Die cuts intricate pieces with precision

- Suited best for small to large production runs

- Vibrating belt system shakes off all scrap resulting in a clean, finished product

Custom Foam Fabrication

Our Foam Fabrication Division utilizes many open- and closed-cell foams to design and fabricate product-specific interior protection.

Tape Converting

We sell and convert various specialty tapes, including repulpable, masking, carton sealing, PTFE, gaffers, and A/V cord tape. We also offer custom services such as die cutting, printed tape, and tape slitting. The BoxMaker is a registered 3M™ Associate Converter.