Paper, Plastic, or Foam: Selecting the Right Protective Packaging Materials

Brands have many options when it comes to selecting protective packaging to keep their products safe in transit. From fiber-based blocking and bracing to inflatable films, foam inserts, bubble wrapping and beyond, the variety of choice can be overwhelming. In addition to identifying the right material and format combination that will best protect the product and fit within budget, today’s brands are also burdened with factoring in sustainability and consumer sentiment into their void fill considerations.

While arriving at your final destination for product protection may seem an arduous task, we can assure you that making a thoughtful void fill material selection can empower your company to not only deliver products intact as intended, but to also delight customers with a smooth unboxing experience, streamline packaging processes to ensure cost-effective shipping and fulfillment, help you achieve sustainability goals, and ultimately reduce operational costs.

To help demystify how to select protective packaging materials that will protect your product, brand, and the planet, we recently sat down with two packaging engineering experts from Pregis to discuss why material choice matters inside the box, what factors impact protective material selection, and how to select the right materials for your packaging to maximize customer lifetime value.

Why Material Choice Matters

The role of packaging is to not only protect your products in transit, but also to promote your brand. The materials you choose to go inside the box are just as important as the box itself.

From an operational standpoint, the materials you choose can have a significant impact on efficiency and cost savings. Certain materials or packaging formats can cut down your pack-out speed by seconds, even minutes, and drastically improve labor output.

For example, replacing rigid custom molded expanded polystyrene (EPS) foam inserts with a malleable die cut polyethylene (PE) foam insert that will conform to your product as it is loaded into a box will save a significant amount of time over the pack-out process.

EPS foam (left) vs. PE foam (right) insert.

Additionally, using the right packaging material will better protect your products during order fulfillment and delivery, reducing the chances of damage or loss.

From a marketing standpoint, your choice of material is a reflection of your brand. If your brand sells natural products, select packaging materials that align with that value. In this case, fiber-based and/or recyclable options are best. The right materials establish brand consistency and adhere to brand identity.

These are just a few of the many ways material choice makes an impact.

The Factors That Influence Material Selection

One of the most significant factors that influences protective packaging material selection today is sustainability. Whether it’s due to regulatory changes or a pivot in business strategy, companies are always brainstorming ways to meet their sustainability initiatives. This is where material selection comes in. The most direct way to achieve these goals is by using recyclable and biodegradable packaging. Examples include but are not limited to compostable packaging, biodegradable plastics, polyethylene foam, and more.

Fun fact: The BoxMaker participates in a foam recycling program. Our foam material waste, including polyethylene and polyurethane, ends right back in the supply stream to be recycled or reground and reused. Learn more about our sustainable materials here.

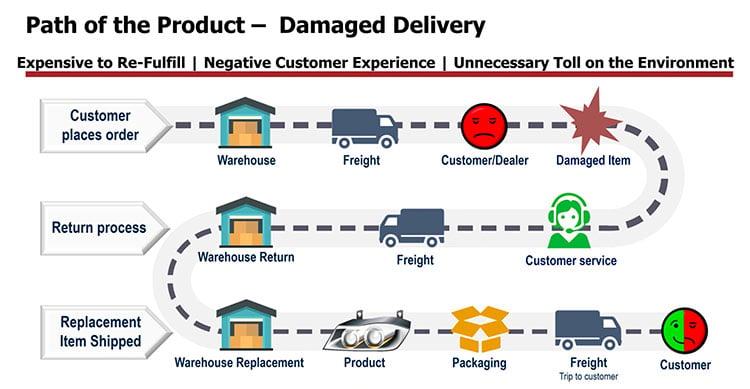

Damage rate is another major factor that influences material selection (perhaps sometimes in hindsight). It is one of the most prevalent issues retailers and e-commerce brands are facing today. Fortunately for companies, reducing damages directly improves sustainability, making it a win-win solution if applied correctly. Properly protected products equate to less returns and fewer overall shipments, which equates to less carbon emissions.

So, while on the surface a foam solution, for example, may not seem like the most sustainable choice as a stand-alone item, when you consider the entire packaging lifecycle and your product (let’s say an expensive medical device), if a foam solution is going to deliver the lowest damage rate, then it may truly be the most sustainable choice.

Different Applications Call for Different Materials

To truly optimize material selection and choose the right packaging solution, it's crucial to realize that different applications require different materials. Selecting the product or material combination that will deliver your desired outcome hinges on your objectives, as each material offers unique attributes and advantages.

To take a more in-depth look at how to evaluate your protective packaging needs and examine the different materials available to you, watch our full webinar, “Paper, Plastic, or Foam: Maximizing Customer Lifetime Value with Packaging” presented by Pregis:

Our team of expert Packaging Advisors can help you evaluate your product protection needs when it comes to packaging. Contact us to start today.

Subscribe

Share this post

Similar Articles

Exploring Alternatives to Foam Protective Packaging

Supply chain limitations are increasing the need for custom fabricated foam alternatives. Explore PE …

What Are Custom Boxes? 4 Key Benefits for Your Brand

Investing in custom boxes is more than an expense; it's a strategic move that yields considerable be …

Why Good Protective Packaging Is Essential for a Great Brand

Protective packaging protects products and preserves a brand's reputation and relationship with cust …